Nelonium: The Next Frontier in Materials

Nelonium, your go-to source for understanding this groundbreaking material concept and its potential to reshape industries. Nelonium is more than just a term; it represents a new era of advanced materials designed to outperform traditional substances in durability, efficiency, and adaptability. Today, we’ll explore what Nelonium is, its origins, applications, benefits, and what the future might hold for this remarkable material.

Concept

At its core, Nelonium is defined as a high-performance material engineered for maximum efficiency and resilience. Unlike conventional materials, which often have limits in strength, temperature tolerance, or environmental resistance, Nelonium is designed to overcome these challenges. It combines elements of chemistry, physics, and nanotechnology to create a substance that is lightweight yet robust, flexible yet incredibly durable.

We can think of Nelonium as a versatile solution for industries that demand reliability and innovation. From aerospace to electronics, its unique properties make it an ideal candidate to replace older materials that no longer meet modern performance standards.

Origins

Nelonium isn’t something that appeared overnight. Its development is rooted in decades of research in materials science and engineering. Scientists and innovators realized that conventional materials like steel, aluminum, and plastics could only take technology so far. To push the boundaries of performance, they began exploring hybrid compositions, nano-scale structures, and synthetic elements that could create superior materials. Nelonium emerged as a culmination of these efforts—a concept rather than a single substance, representing the future of high-performance materials.

Properties

Nelonium is recognized for several defining characteristics that set it apart:

- Strength: Nelonium exhibits remarkable tensile strength, making it highly resistant to bending, cracking, or breaking under pressure.

- Lightweight: Despite its durability, Nelonium maintains a low density, ideal for applications where weight is critical.

- Heat Resistance: It can withstand extreme temperatures, making it suitable for aerospace, automotive, and industrial machinery.

- Corrosion Resistance: Nelonium resists chemical and environmental degradation, extending the lifespan of products made from it.

- Adaptability: Perhaps the most exciting feature is its ability to be engineered for specific needs, whether flexibility, rigidity, conductivity, or thermal management.

These properties are not just theoretical. Engineers have already started experimenting with Nelonium composites in prototypes, demonstrating its real-world potential.

Applications

Nelonium’s versatility allows it to be applied in countless areas:

- Aerospace: Lightweight, heat-resistant materials are critical for aircraft, rockets, and satellites. Nelonium’s unique properties make it a prime candidate for replacing metals and traditional composites in these applications.

- Electronics: Devices today demand smaller, faster, and more durable components. Nelonium can improve circuit boards, casings, and batteries with its thermal stability and strength.

- Medical Devices: Its biocompatibility and corrosion resistance make it suitable for implants, surgical instruments, and advanced prosthetics.

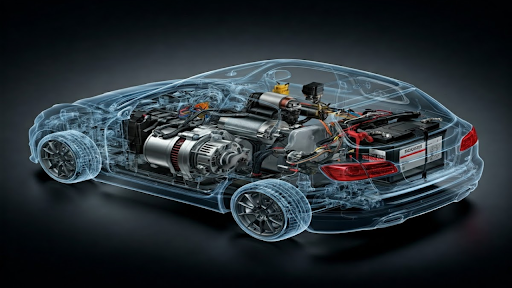

- Automotive: Lighter, stronger materials contribute to fuel efficiency, safety, and performance. Nelonium can be used in vehicle frames, engine components, and high-performance tires.

- Energy: Nelonium composites could improve solar panels, wind turbines, and energy storage solutions, thanks to their efficiency and durability.

It’s clear that Nelonium isn’t just an academic curiosity—it’s a material with the potential to transform entire industries.

Benefits

The rise of Nelonium offers several advantages over conventional materials:

- Efficiency: Products made from Nelonium often require less maintenance and energy to function.

- Longevity: Its resistance to wear and corrosion means a longer life cycle, reducing waste.

- Sustainability: Many Nelonium composites are designed with eco-friendly production methods, making them a greener choice.

- Cost-Effectiveness: While initial development costs can be high, the long-term savings from durability and efficiency outweigh the upfront investment.

- Innovation Potential: Nelonium opens doors to designs and technologies that were previously impossible due to material limitations.

For industries looking to stay competitive, adopting Nelonium-based materials could be a game-changer.

Challenges

No innovation comes without hurdles, and Nelonium is no exception.

- Research and Development: Producing Nelonium at scale requires extensive R&D, sophisticated equipment, and precise engineering.

- Cost: The initial costs of developing and manufacturing Nelonium can be higher than traditional materials.

- Standardization: Because Nelonium is a new concept, industry standards and certifications are still in development, which may slow adoption.

- Processing: Some Nelonium composites may require unique manufacturing techniques that are not widely available.

Despite these challenges, the potential benefits continue to drive research and investment, ensuring that Nelonium will remain a focus for innovation in material science.

Future

Looking ahead, Nelonium is poised to become a cornerstone of advanced material technology. Researchers are exploring ways to enhance its properties even further, including self-healing capabilities, adaptive strength, and enhanced conductivity. As production techniques improve and costs decrease, Nelonium could become a standard material in aerospace, electronics, construction, and even consumer goods.

We can imagine a world where cars are lighter and more fuel-efficient, electronics are more durable, and medical devices last longer with minimal risk of failure—all thanks to Nelonium. Its potential isn’t limited to industry; it could influence the way we live, work, and interact with technology on a daily basis.

Quick Info

- Type: Advanced material concept

- Key Properties: Strength, lightweight, heat resistance, corrosion resistance, adaptability

- Applications: Aerospace, electronics, medical devices, automotive, energy

- Benefits: Efficiency, longevity, sustainability, cost-effectiveness, innovation potential

- Challenges: High R&D cost, production complexity, standardization, processing limitations

Conclusion

Nelonium represents a leap forward in material science. Its combination of strength, adaptability, and efficiency offers a glimpse into a future where materials are no longer the limiting factor in technological innovation. While challenges remain, the opportunities it presents are vast and transformative. By embracing Nelonium, industries can build stronger, smarter, and more sustainable solutions that redefine what’s possible in technology, medicine, energy, and beyond.

Nelonium is not just a material—it’s a vision of the future.